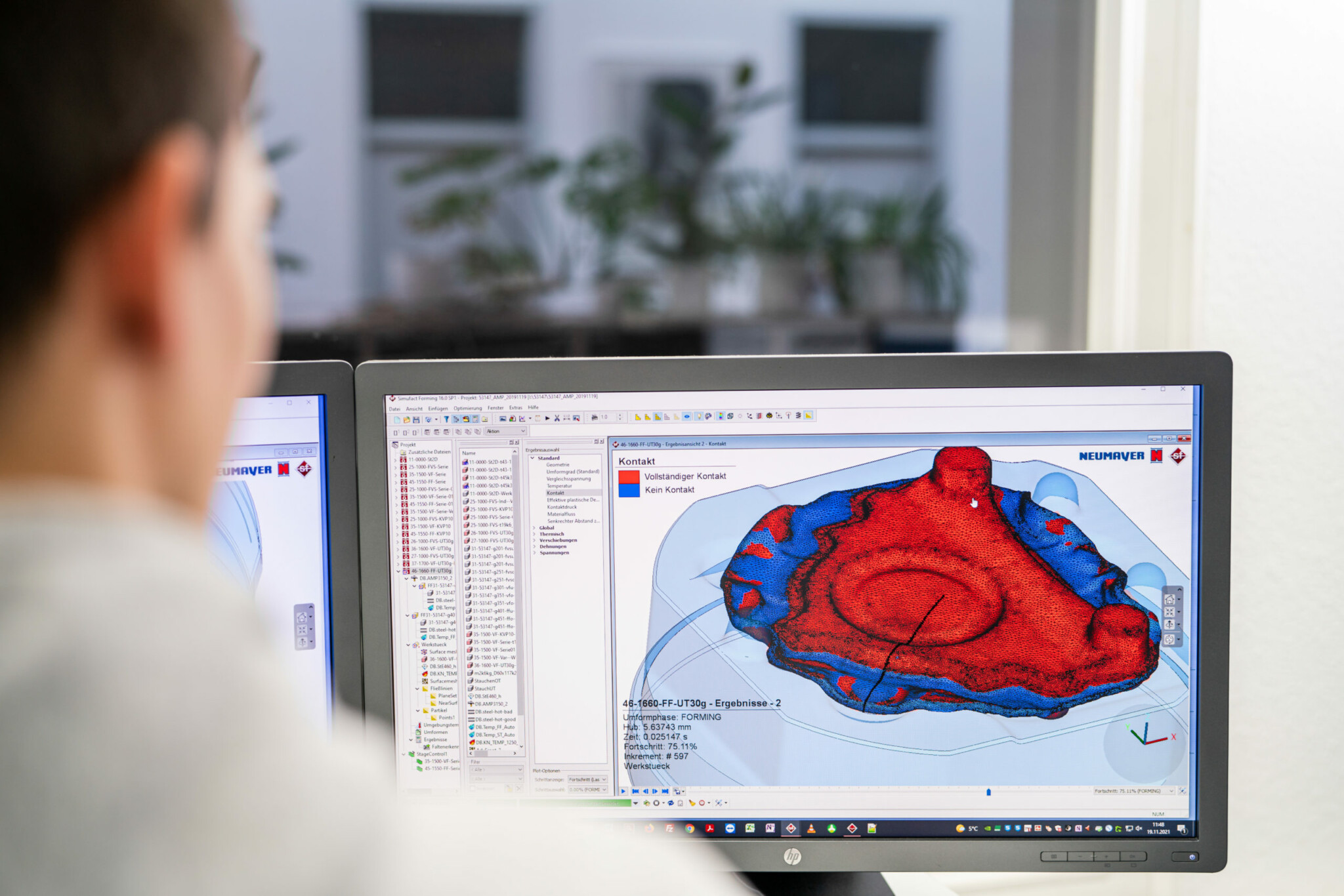

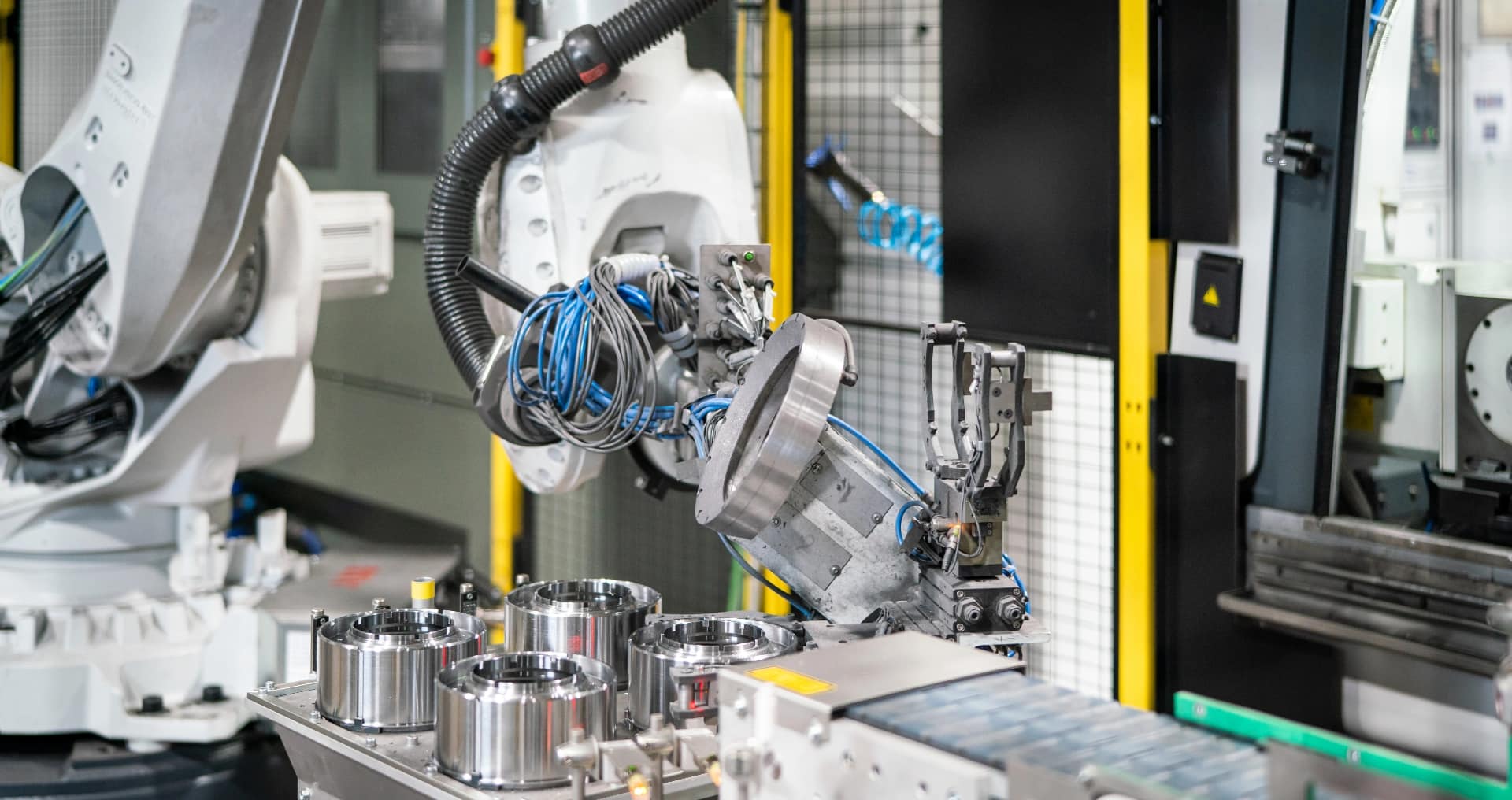

Developing with innovative ideas

Components, modules, systems, assemblies: our engineers puzzle out the most complex of challenges using state-of-the-art development and simulation tools. In close communication with our customers, and keeping the entire value chain in mind, we work out sophisticated concepts, streamlined processes and opportunities for cost savings.