The third and fourth generation: Richard Jr. and Albert Neumayer – on the way to becoming a modern industrial company

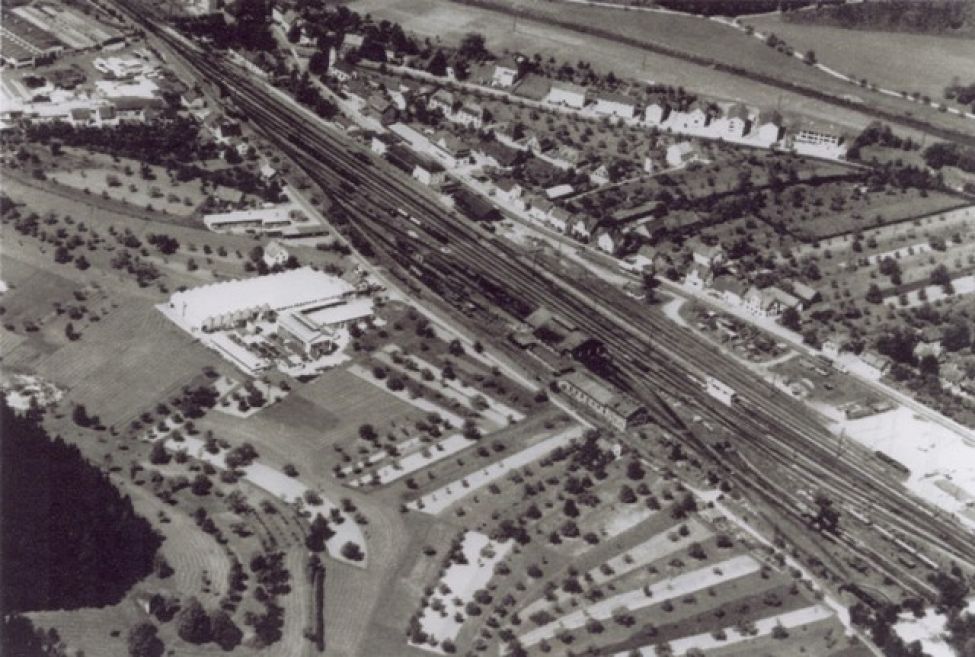

Richard Neumayer Jr, born in 1909 as the eldest son of Heinrich Neumayer, is released from military service during the Second World War to work in production, which is vital to the war effort. In 1940, he took over the management of the forge in Gutach and the newly established production of turned parts. After a fire in 1945, he decided to make a fresh start and rebuilt the drop forge in Hausach.

Together with his wife Johanna, née Gruber, he starts there with three employees; a little later there are already seven. With a great deal of commitment and entrepreneurial vision, the couple succeeded in further developing the originally craft-based business through continuous investment and great personal dedication.

In 1966, there is another fire in which machines and parts of the building are damaged. Production continues under the open sky for 14 days. In the years that followed, the company grew steadily. The number of employees rises from seven to over 180, to which the progressive mechanization and expansion of production contribute significantly.

In 1975, Albert Neumayer, son of Richard Jr. and Johanna Neumayer, joins the company at the age of 29. After the death of his father in 1980, he takes over the sole management of the company. The generational change is accompanied by technological developments. The product range is expanded and new production processes are introduced.

By the mid-1970s, the company was already producing drop-forged parts weighing between 0.2 and 20 kilograms from various steel grades. The production facilities include forging hammers and presses with press forces of 1,000 to 8,000 kilograms. The company also has a modern die shop and heat treatment facilities. Even then, great importance was attached to quality assurance with appropriate testing equipment.

Customers include the automotive industry, mechanical and apparatus engineering, construction and agricultural machinery, shipbuilding and the chemical industry. In 1953, the product range was expanded to include flanges according to DIN, ASA and customer specifications. High-quality stainless steels are also processed. Production is TÜV-certified and quality remains a key feature. New customer sectors are added, including plant engineering.

In 2000, the company puts the first fully automatic press line with a pressing force of 31,500 kN into operation. Further investments in modern technology follow, including a forging press with a pressing force of 2,000 tons. Production is increasingly computerized. The control of the machines and the design of tools and equipment are supported by digital processes. The stock includes various types of steel as well as numerous order-related tools.

In 2003, Günther Keppler joins the company and shares the management with Albert Neumayer. Keppler is replaced five years later by Sales Manager Erwin Aberle. Under the joint management of Albert Neumayer and Erwin Aberle, the company continues to grow. In 2015, a new building complex is constructed with space for shipping, logistics, social rooms, the warehouse for forming tools and the extended mechanical processing department.

Albert Neumayer is also involved in his home community. He supports the Hausach school center with sculptures by Frieder Haser and the entrance area of the town hall with a work by Herbert Maier. In 2011, he was awarded the town of Hausach’s plate of honor for his many years of commitment to his community.

In 2017, Dirk A. Neumayer joins the management team as a representative of the 5th generation and runs the company together with his father Albert Neumayer until 2020.