Controlled cooling – an important contribution to climate protection

At Richard Neumayer GmbH, we are constantly working to make our manufacturing processes more efficient and climate friendly. A crucial element of this transformation process is controlled cooling, which allows the heat generated during forging to be strategically reused — significantly reducing overall energy consumption.

In conventional manufacturing practice, forged parts are first cooled after forming and then reheated for subsequent heat treatment, which requires a great deal of energy. This process is not only inefficient but also associated with high emissions. Controlled cooling, on the other hand, makes targeted use of the existing forging heat to keep the components within defined temperature ranges. This eliminates the need for reheating, which significantly reduces energy consumption (95 percent less natural gas), CO2 emissions and, in the long term, production costs. At the same time, the thermal treatment can be made reproducible and process reliable.

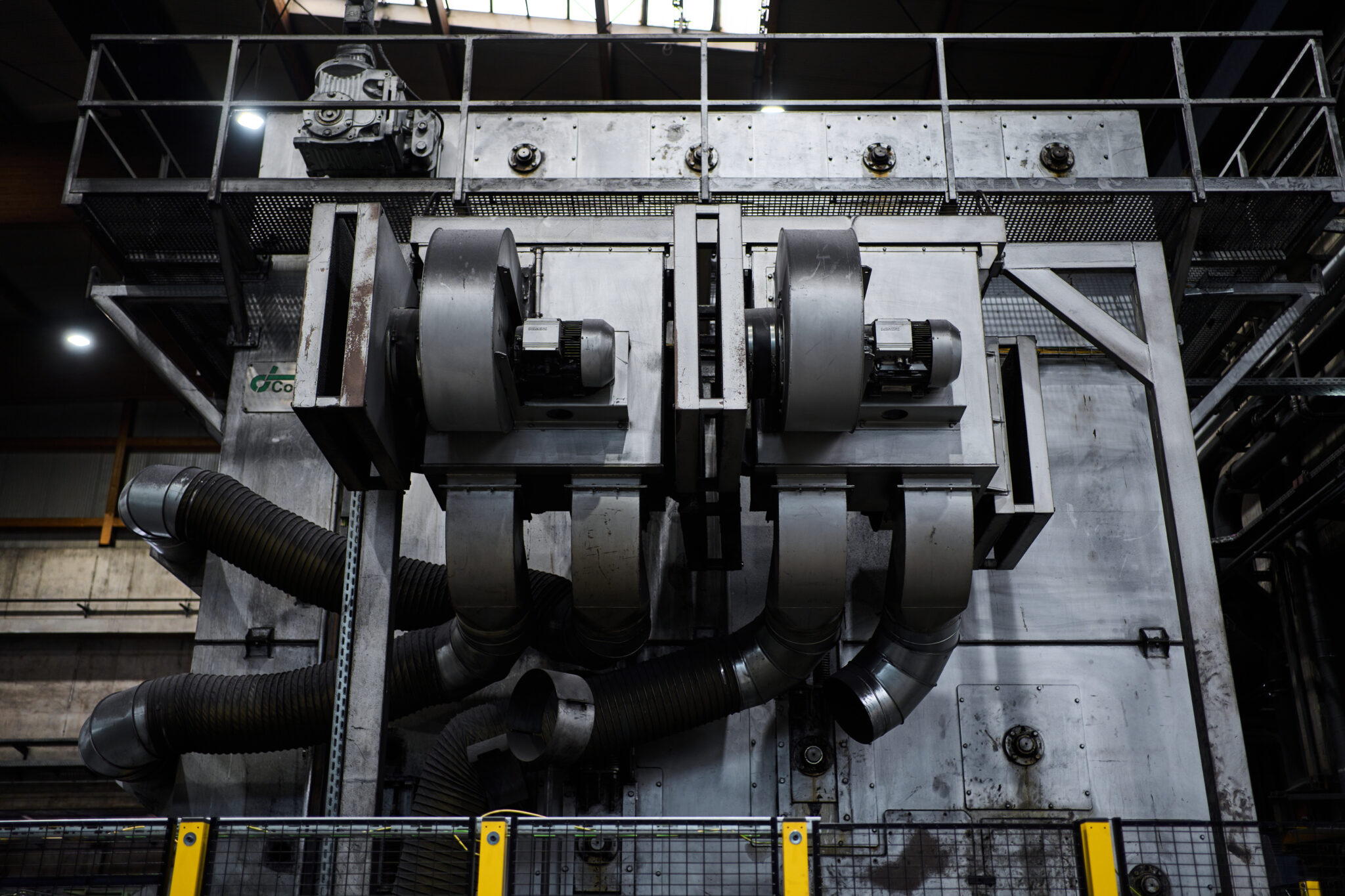

We have developed our own technical solutions to make optimum use of the possibilities offered by controlled cooling. These include specially designed cooling belts and insulation containers. These ensure that the temperature control is precisely matched to the respective component geometry. This not only saves energy, but also reliably achieves the desired material properties. In addition, we advise our customers on material alternatives where the process is possible.

Controlled cooling is now an integral part of our manufacturing strategy and offers further potential. Alternative heat treatment also helps to reduce CO2 emissions in the supply chain and improve the environmental balance of products.

A practical example: CO2-neutral drive component

As part of a project to develop a CO2-neutral drive component, Richard Neumayer produced a product that was completely CO2-neutral across the entire process chain for the first time. The forged part – an axle drive wheel for an electric transmission – was made from CO2-reduced steel. Controlled cooling played a key role in this: immediately after forging, the components were kept at the right temperature in specially developed insulated containers, so that no additional heat treatment was necessary. In combination with other measures – such as the use of green electricity and the offsetting of unavoidable residual emissions – it was possible to completely neutralize the CO2 footprint in production (cradle-to-gate, Scope 1 and 2, and selected Scope 3 categories).

This was only possible thanks to close coordination with our customers and development partners. New processes must be validated – in other words, they must function in a traceable manner, be documented and approved. This requires trust, openness and cooperation based on partnership.

Our climate strategy

As an energy-intensive company, we see it as our responsibility to take concrete steps to reduce our emissions. Controlled Cooling is one such step within our comprehensive climate strategy. We are guided by the goals of the Paris Climate Agreement and the European Green Deal. In addition, we have joined the Science Based Targets Initiative (SBTi). By 2030, we aim to reduce our direct emissions (Scope 1 and 2) by 50%. We are striving for climate neutrality by 2050. ‘Climate protection is the responsibility of our generation,’ says CEO Dirk A. Neumayer. ‘We want to actively contribute to making a climate-friendly industry possible – through innovation, consistent implementation and partnership-based cooperation.’